Yellow Hardener in the Bottle, and Shelf Life

- Michele Donohue

- Dec 12, 2020

- 4 min read

Updated: Nov 18, 2024

Typically, even though resins have a shelf life of 12 months, many epoxy resins are ideally best used within 3 months of purchase (and up to 6 months of purchase for others). Try not to purchase more then you will use up in a reasonable period of time.

Yellowing in the bottle: Yellowing in the bottle occurs in all resins, and it is usually from oxidization, (from exposure to oxygen not from exposure to uv light). It's very exaggerated & much more noticeable in the larger sized containers. Some resin companies use white or black (opaque) containers so you don't see (or notice) the yellowing as much as you do with clear containers. Most in many cases, once mixed, the epoxy will be clear and not yellow (if it's within the year shelf life).

Yellowing of hardener in the bottle can happen for numerous reasons. Sometimes it appears Part B is yellowed just because it's a different colour then the part A. This does not automatically mean that it has yellowed perse. It may be that it's not yellowed, but just a different tone than part A. In some epoxies, it is normal to have two different colour tones between the resin and hardener bottles!!!

If a resin kit arrives with a slight yellow to it, It can also be from UV inhibitors that are an added ingredient, as they are actually yellow in colour.

Yellowing of hardener can also be caused by oxidation which happens to every brand.

If an unopened hardener has gone slightly yellow before the one year mark, it could be from the plastic (HDPE) bottles, since they do breath a little, allowing some oxidation to still occur (even without opening). This is another reason why it's important to use shortly after purchasing. If you're waiting a few months months before using, you can expect it will begin to change colour. However as stated before, it will still work fine.

All resins have a fairly common shelf life, which is 6 months once opened, and 12 months unopened. People can & do use epoxy past its shelf life, however if using up older resin, use coloured and darker tints (rather then clear). When mixed, a slightly yellowed hardener may go clear or pretty close to it, if within the year shelf life. It will appear less yellow once on a piece due to the fact it is mixed with the other part (A) resin, which dilutes it, and once spread out it's less observable to the eye.

One trick many long time resin users do with slightly yellowed hardener, is some people add a tiny drop of blue or violet tint (nothing with micas), to the mixed epoxy to trick the eye from seeing the yellow. This trick, sometimes allows people to use up resin that is no longer new, and in it's ideal time frame.

If the product has gone into the deeper darker amber tones, then it's well past it's shelf life, or it's been exposed to more oxygen then it should be (possibly lid not tightened), or there may be some type of contaminant in it, & I wouldn't use it. It needs to be properly disposed of. Though I have heard of a few woodworkers who still use that badly aged resin, as a base layer/sealer in projects it won’t be seen)

You will also sometimes notice a difference in smell of aged (ambered) hardener. It will often have quite a bit stronger odour than when it's brand new, again due to oxidization process.

Many people still use their slightly aged ambered hardener, and find it can still work on base coats, or wood or other projects where colour is not important, but we do not recommend using to topcoat anything where colour is important. You may also find aged and ambered resin products have a shorter pot life, and you may need to apply it much quicker once two parts have been mixed.

Ideally, its recommended not to buy more then you will fully use up within 6 months of purchase, and plan to use it ideally within 3 months of receiving. Although it's tempting to take advantage of volume pricing or sales, it may not be worthwhile if product is not going to be used up within 3-6 months, dependant on types of projects you are working with.

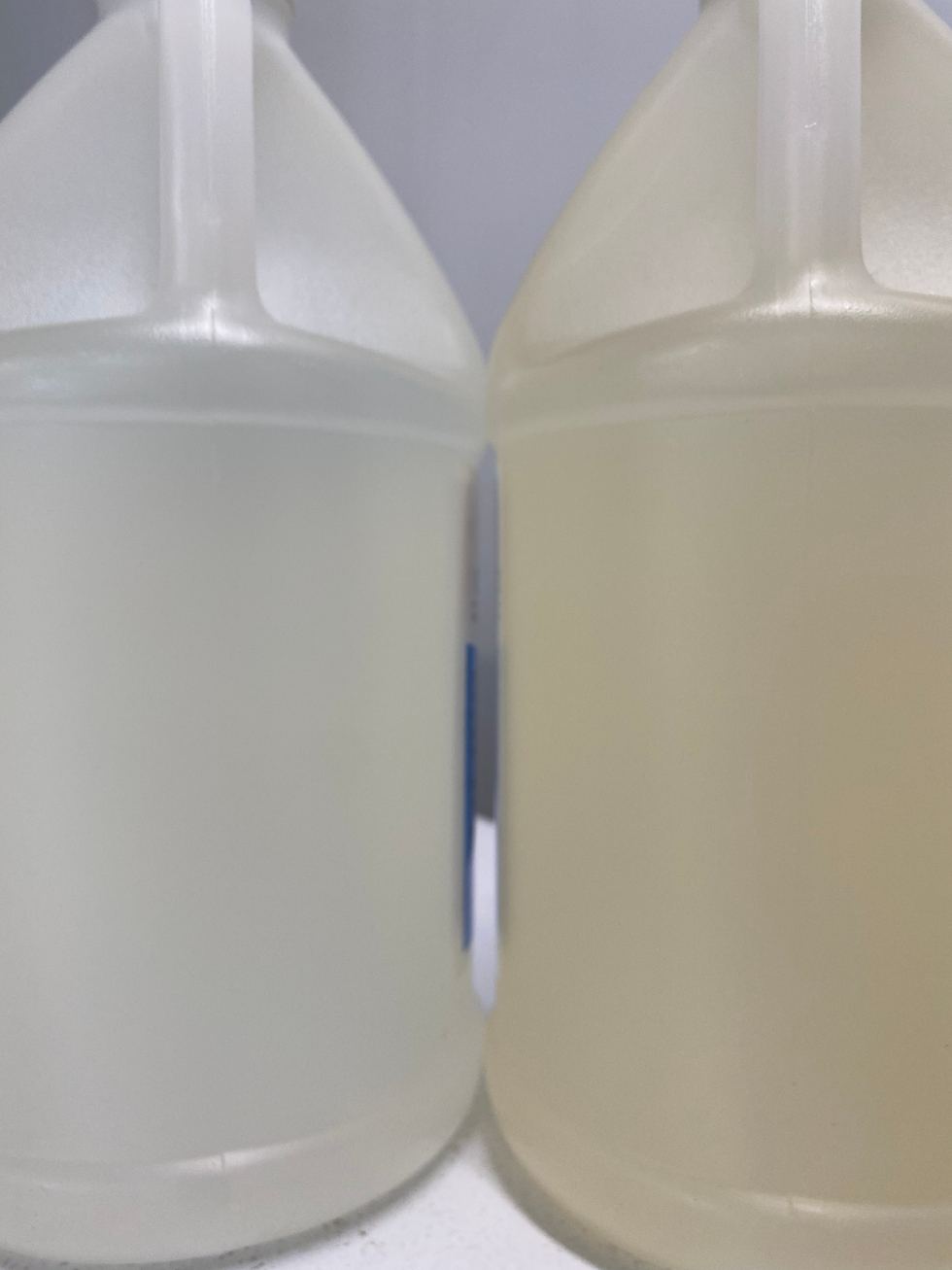

Example of ambered hardener.

***Example of a more commonly seen hardener with a slightly different colour tone than part A. This is very normal for certain types of resin!!! ***. In this photo, this product is not ambered or aged, this is how it looks when it's produced! Once mixed according to manufacturers directions, the final results will be beautiful and clear.

Shelf Life/Storage:

Store product in a dark but well ventilated area that is above 10C. If product happens to freeze, let it thaw completely, and return to room temperature (there is a blog post on our website about how to best thaw frozen resins).

Most resins all have a shelf life of up to 12 months unopened, and 6 months once opened (ensure lids are replaced tightly). The reason is due to oxidization. When the hardener in any resin is exposed to oxygen, it has a yellowing effect.

Even once past shelf life, the product still works, and will still cure. But older very ambered product may produce more bubbles depending on resin type. You may want to just use it up only with darker colours (or tinted over wood).

Most epoxy resin products used in our art world, have UV additives. Optimally, try to plan to purchase only as much resin as can be used in a 3 month period if possible.

If you tend to make smaller items, like jewellry, purchase the smaller kit sizes. As tempting as it is to take advantage of the lower per oz prices in larger containers, it's not helpful, if it's sitting on the shelf, and no longer fresh by the time a person goes to use it.

Always wipe around the bottle openings, when done so that a powdery substance does not form and drop particles into the bottle when opened again.

Please keep containers tightly sealed when not in use.

.png)

Comments